Engineering

ENGINEERING = Core Competency

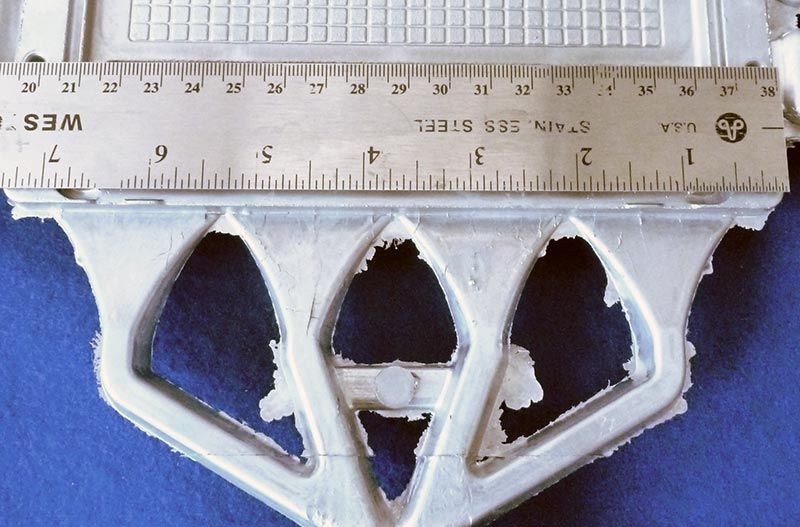

IMG’s Engineering support evolved from over 50 years of building molds (In-house) initially for the plastic injection molding industry and quickly adding die cast molds to the core list of services. Mold and tool building is still completed in-house.

In this day in age it is even more important to be flexible, cost effective, and solution-driven to meet your needs. Our Engineering systems are founded on meeting your needs.

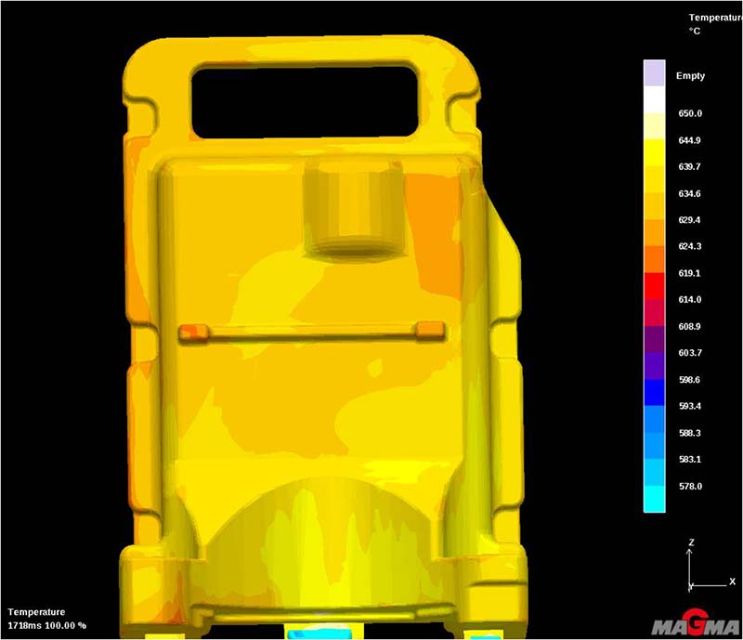

Current Engineering systems originate with extensive review of our customer’s requirements – part design, tolerancing, form-fit-function analysis, budget, and more along with:

- CAD/CAM

- SolidWorks

- MasterCam

- Cost effective tooling

- On-time delivery of tooling

- DFM – Design for Manufacturability

- DFR – Design for Reliability

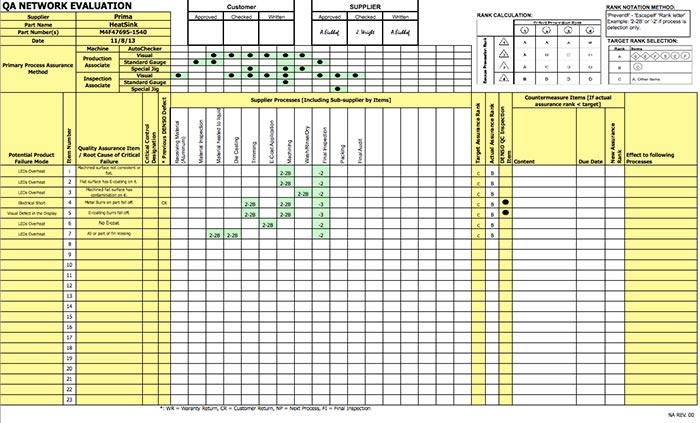

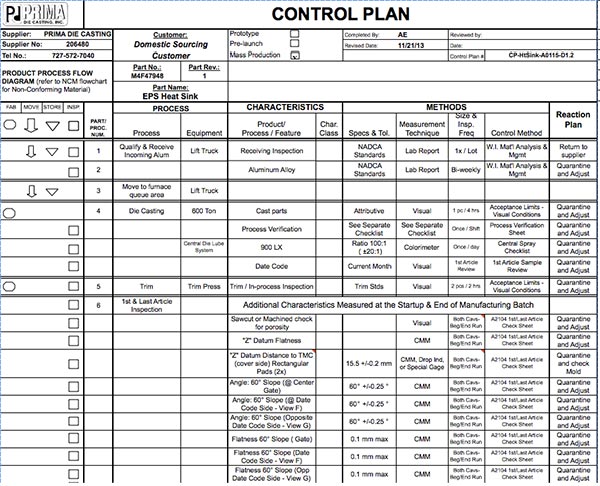

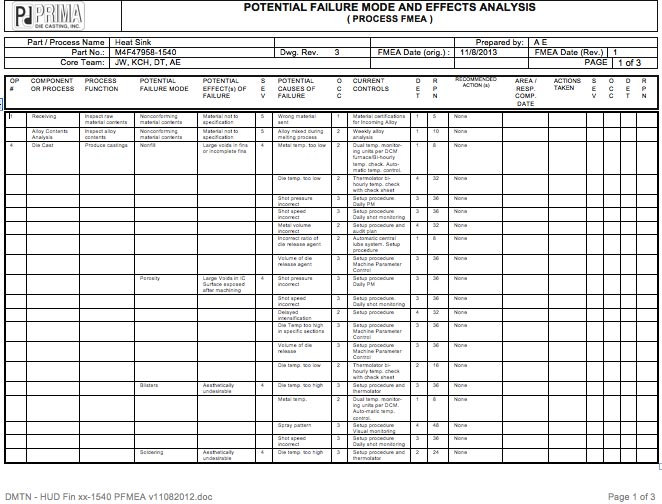

As a custom manufacturer, IMGs operation is well-suited for a variety of customers and applications. We have the ability to apply modern APQP systems utilizing the AIAG Core Tools:

- dFmea,

- pFMEA,

- PPAP,

- MSA,

- SPC,

- Control Plans,

- and more,

- Tools are applied cost effectively as needed / defined for each customers.

We also have the ability to apply less complex and less costly applied ENGINEERING systems to support more budget sensitive customers such as entrepreneurs, start-up companies, and smaller closely-held companies.